This was my last large project before I retired my company.

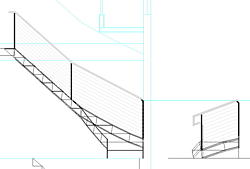

The major challenge here was squeezing a code staircase inside a non-code space.

This required the treads to be carefully located in space using computer coordinates so it had a proper rise and run while turning in such a way that your head cleared the ceiling beam.

The architect just gave me numbers and left it to me to play connect-the-dots in space.

The idea of an extremely light weight and yet rigid staircase came from my history in theatre using lighting trusses. The entire stair unit weighed around 300 lbs., allowing 2 people to carry it in and stand it up, and yet standing on it was like standing on concrete.

The cable rails were an additional challenge. We ended up using drift-net cord from a fishery supply store. It has a nylon outer sheath that could be acid dyed to match the stair runner, but the inner fibres are stronger than steel cable and now over 10 years later still have not stretched.

After tensioning the cables you could strum them like a huge harp. Quite musical.

The balcony rail and lower stair rail were later projects on the same house.

I was always glad that they were my last major clients since the project turned out so well.

Balcony rail

Balcony rail

Balcony rail

Balcony rail

Balcony rail

Balcony rail

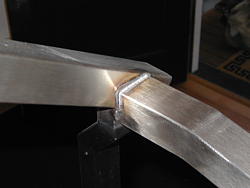

Stairs construction

Stairs construction

Stairs construction

Stairs construction

Stairs construction

Stairs construction

Stairs construction

Stairs construction

Stairs construction

Stairs construction

Stairs installation

Stairs installation

Stairs installation

Stairs installation

Stairs installation

Stairs installation

Stairs installation

Stairs installation

Stairs installation

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Railings

Stairs completed

Stairs completed

Stairs completed

Stairs completed

Stairs completed

Stairs completed

Stairs completed

Stairs completed

Stairs completed

Stairs completed

Stairs completed

Stairs completed

Stairs completed

Stairs completed

Stairs completed

Stairs completed

Stairs completed

Stairs completed

Stairs completed